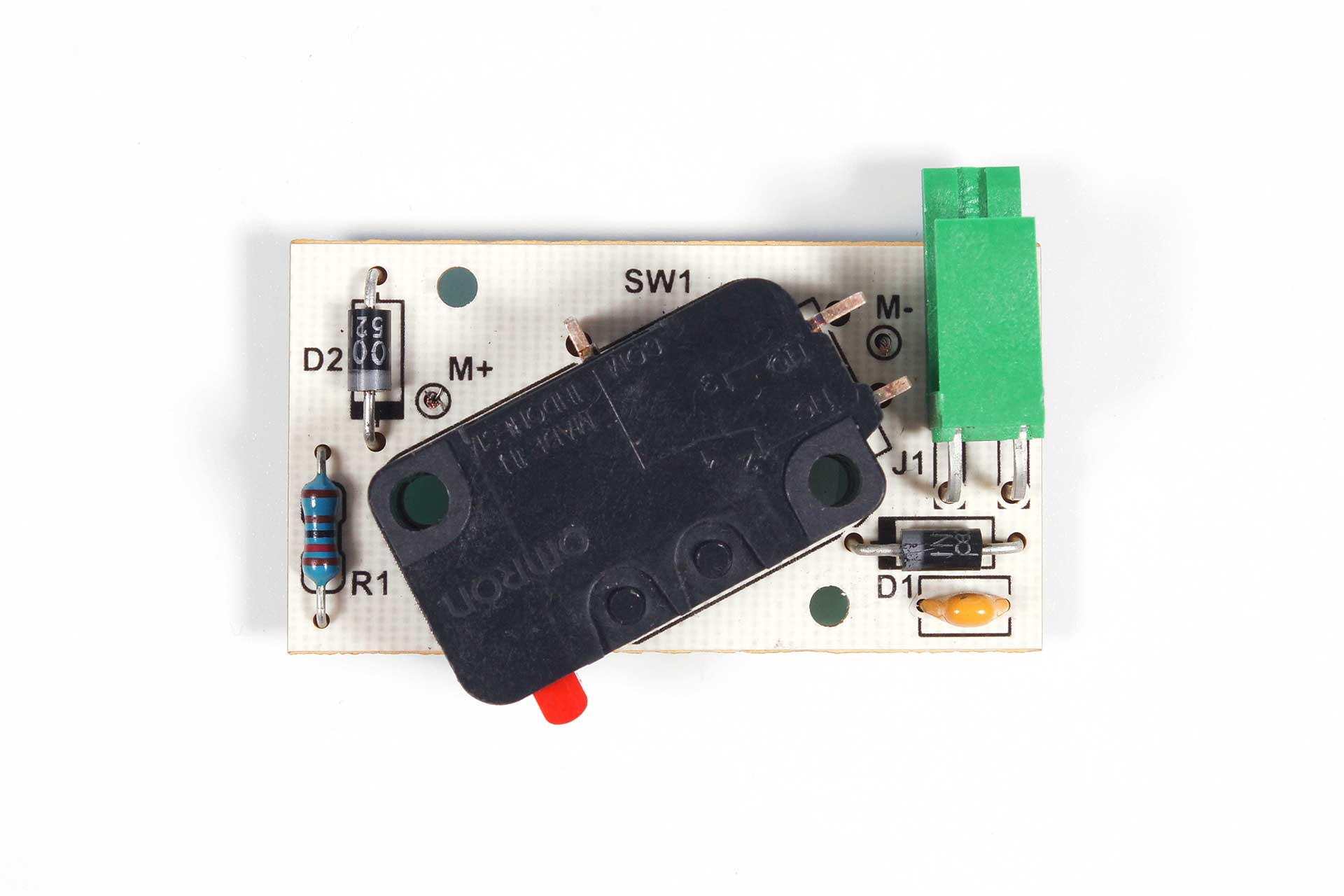

Case History 3

An important customer in the Horeca market uses this simple PCB to check the limit of vending machines devices. We are talking about a product that is managed in hundreds of thousands of pieces every year and which, despite its evident simplicity, presents a series of critical issues mainly related to the precision of the positioning of the microswitch.

Their Far East supplier was unable to guarantee a constant compliance with the project specifications and the defect index in the production line had reached unacceptable levels.

Nordgas has been involved in this project and, thanks to our experience on the process, by introducing some technological solutions and by automating some phases of the production cycle, we have been able to significantly improve the quality level of the product. The introduction of these solutions has allowed us to strongly reduce manual skills to the advantage of the sale price. We were therefore able to:

- Be economically competitive with respect to the previous supplier by relocating production from the Far East to Europe

- Having reached an excellent quality level by eliminating rejections from the line

- Having reduced production and supply times

- Ensure easier warehouse management and reduced financial exposure by the customer

All without any additional cost on the purchase price of the single product.