R&D

NORDGAS presents a complete and structured Research & Development department which translates Customers’ needs into products. Our vertical structure operates in complete autonomy in the following design phases:

- Mechanical design

- Hardware design

- Firmware design

- PCB layout design

- EMC Test Lab

- Product industrialization

We are also able to manage co-projects in partnership with the Customer, by sharing all the development phases, with the aim of creating Customer-tailored products.

A dynamic and motivated Company: the ideal partner to accommodate the widest choice of services, ranging from simple product industrialization up to the complete “turnkey” solution, where NORDGAS takes care of all the project development phases.

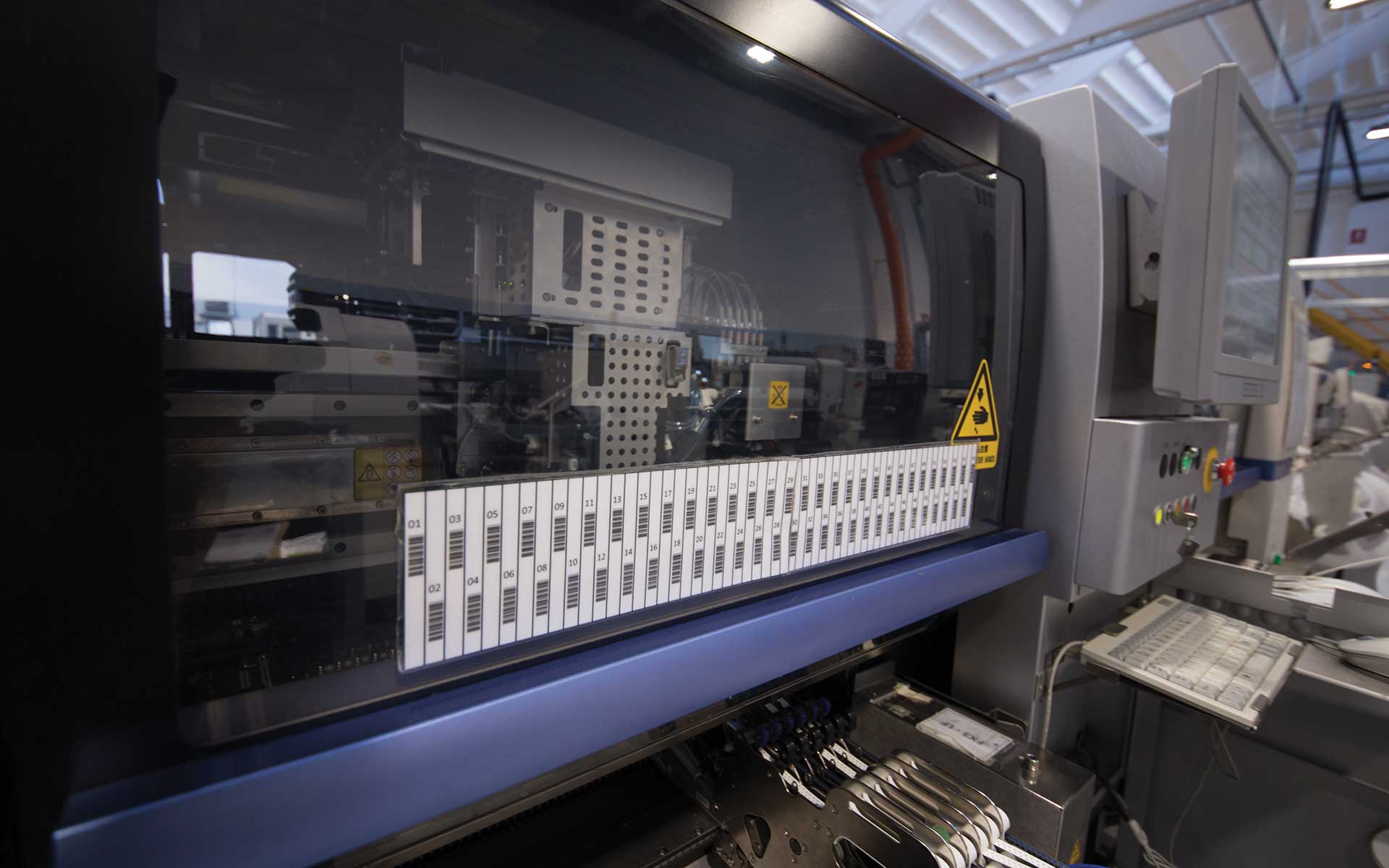

Production & testing

Process control and monitoring is our life objective. Our new, fully equipped and cutting-edge technological electronic board production plant consists of:

- Three SMT assembly lines.

- An automatic combined PTH axial – radial assembly line.

- Two welding lines.

- Four full-automatic testing lines (Parametric & Functional Testing) for a complete test of each product made.

- Several semi-automatic testing lines (Parametric & Functional Testing).

Some of our production lines are also dedicated to the assembly and production of finished products, conceived and designed by other Companies, or in co-design with Nordgas, mainly in the lighting, home and building, industrial sectors.

All of this allows NORDGAS to accommodate every type of production requirement.

Quality

NORDGAS pays special attention to the total quality in terms of products. The experience gained in the production of burner control boards certified as safety products requires extremely high-quality standards.

We pay the same care and attention to all those products that normally do not require such quality levels. This allows us to differentiate ourselves from most companies that deal with simple electronic assemblies.

Constant investments in automation of production processes and tests have led us to eliminate one series of manual operations with a significant benefit in terms of efficiency and quality.

The on-going improvement process is guaranteed by the Kaizen technology which NORDGAS has been applying in all business sectors, in addition to ISO 9000 certification which guarantees supervised processes, regularly tested.

Some custom project realized for our clients

Case History #1

One of the most important player of the hydronic solutions assigned us the design of their heat metering system.

Read moreCase History #2

One of the most important hydronic solutions manufacturers, assigned us the project of their new “Thermostatic regulation system”.

Read moreCase History #3

An important customer in the Horeca market uses this simple PCB to check the limit of vending machines devices.

Read more